CONTEXT

Over the centuries, many devices have been invented to basically understand mechanics before it can be so widely understood and studied. A great understanding of skin mechanics is then a gateway to characterize mechanics properties of human skin and allows to observe its behavior under laws of elasticity*, torsion and force, which together are known as « Hooke’s law ».

Definition

Hooke’s law, applied on skin, is a principle of physics modeling its deformation* under external stretching, compressing, or bending. This law of elasticity is a link between the displacement or size of the deformation and the deforming force or load. This is why skin returns to its original shape removal of the load.

This ability to return to a normal shape after experiencing distortion is named « restoring force ». Refering to Hooke’s Law, this restoring force is generally proportional to the amount of stretch* experienced by the skin. The law may also be expressed in terms of stress and strain.

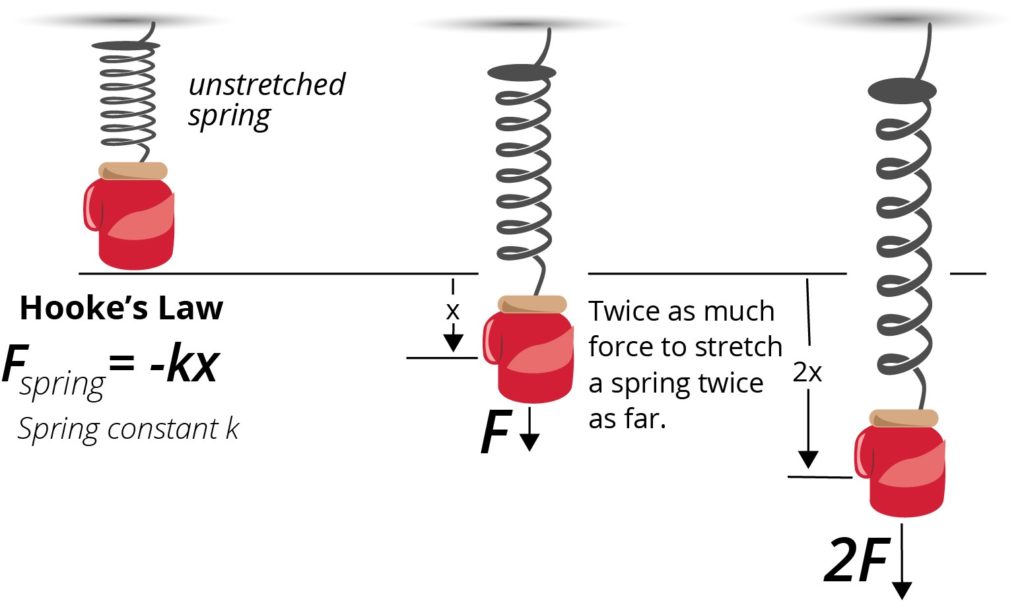

Hooke’s law can be formulated as:

F = -kx

Where :

- F is the force

- X is the length of extension/compression*

- k is a constant of propotionality, which is usually given in N/m. Its value depends not only on the kind of elastic material under consideration, but also on its dimension and shape.

Figure 1 : Illustration of Hooke’s law, showing the relationship between force and distance when applied to a spring.

Hooke’s law story

Behind this law, Robert Hooke, a 17th century British physicist who gave his name to it, demonstrated a relationship between the forces applied to a spring and its elasticity. Thanks to this experience, he noticed that the stress vs strain curve for materials such as skin, has a linear region. This law was first extracted in 1660 from a latin anagram, and then used as a solution in 1678 under the form « ut tensio, sic vis », that means in english « as the extension, so the force » or « the extension is proportional to the force ».

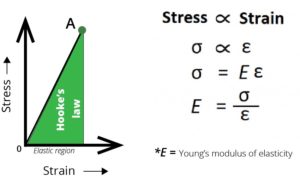

One century later, Hooke’s law could relate strain to stress in the linear elastic domain, thanks to a modulus named… Young’s modulus.

Young’s modulus

Young’s modulus is a numerical constant, named by the 18th century english physician Thomas Young. It describes the object’s resistance to being deformed elastically while an external force is applied to it. Young’s modulus is equal to the longitudinal stress divided by the strain.

What is the difference between Hooke’s law and Young ‘s modulus ?

Hooke’s law is a fondamental rule of thumb applied on skin that describes a direct proportionality link between the force applied on an object and the induced strain. Young’s Modulus is a constant coefficient stiffness*, named k, which describes how stiff is the skin or how likely it is to deform. Young’s modulus can be derived by compressing the skin then measuring the stress and strain.

Figure 2: Stress and strain curve at the Hooke’s law scale.

Application on skin

According to Hooke’s law, elastic behaviour of a material is partly due to small displacements of its constituent molecules. These displacements are also proportional to the force caused by displacements themselves.

The skin is defined as perfectly elastic as it returns to its initial shape after applied forces. Then skin plays under mechanical laws that might redefine its own properties.

WHY AFM?

AFM aquires any information about skin mechanical properties that are measured with an optical system spotted on a cantilever. From the deflection of the AFM, the force can then be calculated with the Hooke’s law, when the spring constant is known.

On the scale of a more than 300 years old’s law, AFM represents one of the most modern and efficient methods to characterize elastic properties of the skin.

Two famous physicists from respectively 17th and 18th century, many developments on skin research and a vibrant BioMeca’s team to bring you powerful tools to revolutionize in vitro and ex vivo efficacy tests.

LEXICAL

- Deformation: change in size or shape of an object.

- Elasticity (or elastic deformation): temporary change in length, volume, or shape produced in an elastic substance by a stress.

- Stiffness (or rigidity): the extent to which an object resists deformation in response to an applied force (measured in N/m).

- Stretch: cause a material to become longer or wider than usual as a result of pulling at the edges.

- Compression: the act of pressing a material into a smaller space or putting pressure on it from different sides until it gets smaller.

Discover our study cases

Tensing effect

Smoothing effect

Skin barrier

Follow our other news

The relationship between skin elasticity and viscoelasticity

24 January 2024

24 January 2024Are you a smoker? Here’s how it affects your skin!

29 November 2022

29 November 2022Why are simplicity and multifunctionality new trends in the beauty market?

19 October 2022

19 October 2022